Starting Date: aug 2023

Number of Partners: –

Total Budget: –

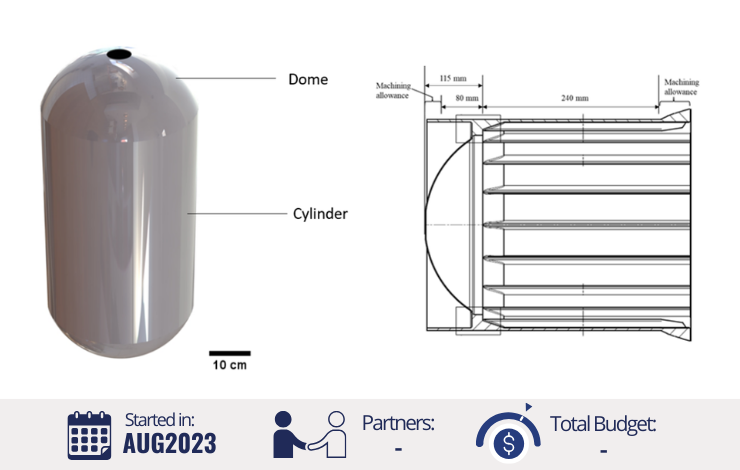

In conjunction with NOVA FCT, two German manufacturing companies have developed a new method for manufacturing propellant tanks for the and European Space Agency that reduces the need for machining and friction stir welding processes.

This approach involves manufacturing a tank half starting from a single metal plate, using innovative and advanced metal forming processes followed by orbital welding of two tank halves.

The AFT project introduced a groundbreaking approach, utilizing advanced techniques like Hot Stretch Forming, Magnetic Pulse Forming, Hub Forming, Spinning, and Integrated Stiffened Cylinder Flow Forming to shape a tank half from a single metal plate.

The objective is to conduct a comprehensive Life Cycle Assessment (LCA), comparing the environmental impacts of the traditional and AFT-based methods using AA2219 aluminum alloy as a reference. This groundbreaking project signifies a significant leap toward environmental sustainability and cost-effectiveness in spacecraft propellant tank manufacturing.