DIPS

The main goal of DIPS is the design and implementation of digital-based solutions to improve organizations’ efficiency, resilience, and circularity. The DIPS Lab focuses on R&D activities to develop and apply state-of-the-art sustainable digital solutions in production systems considering a life cycle perspective, from product development to production and distribution, from operation to disposal.

Topics of interest include business analytics, augmented reality/virtual reality, blockchain technology, artificial intelligence, namely machine learning, deep learning, computer vision, and natural language processing and their integration with production systems and processes. The DIPS Lab explores case studies and provides equipment to address problems in manufacturing, namely process monitoring, optimization, and digitalization, and maintenance, including forecasting, planning, and scheduling.

EQUIPMENTS AVAILABLE IN OUR LABORATORY INCLUDE:

Dell Precision 3660 Workstation (software: GeNIe Bayesian Nets; MATLAB)

8x Intel i7 PC (software: SolidWorks; MakerBot; Creality)

Workstation Amitronic Ryzen 5 2400G 8GB with LCA (software: SimaPro)

Automated Warehouse (Intelitek)

ELITE ROBOTS Model EC63

ELITE ROBOTS Model EC66

Transfer system /conveyer TS2 plus with 2 meters

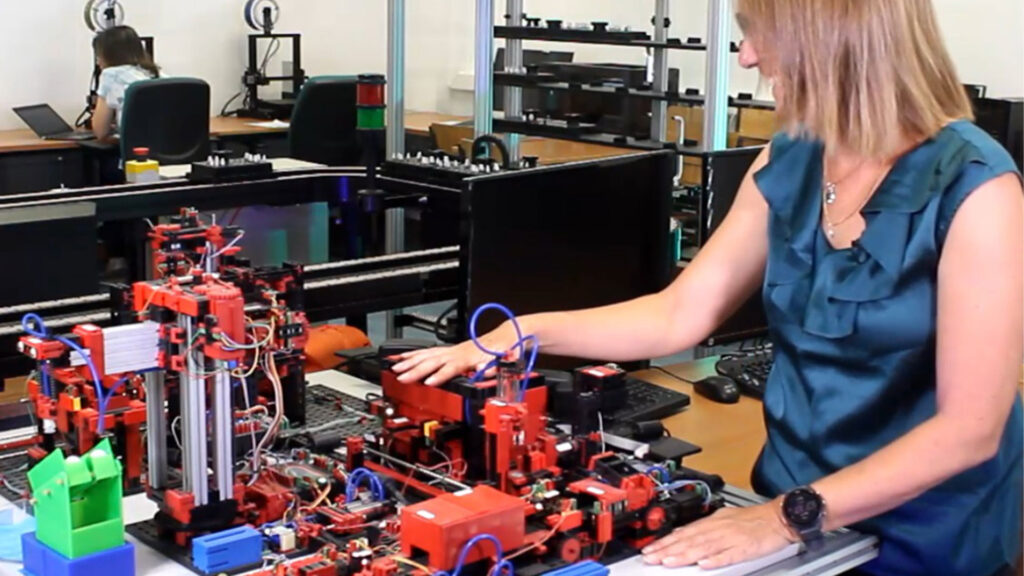

FischerTechnik micro factory

Creality Ender 3D Printer (2)

MakerBot Replicator 2 3D Printer

PICO 4 RV Glasses (2)

Meta Quest 2 VR Goggles

Samsung Interactive Screen with support and AVER video conferencing system

THIS LABORATORY PROVIDES SUPPORT TO DIFFERENT PROJECTS SUCH AS:

AFIMAir – Accurate Forecasting & Inventory Management in Aviation

Blockchain Decentralised Asset Management Tool for Industrial Symbiosis Ecosystems (BECAME)

DIGITAL UNICORNS

Our Digital Future

MY-GATEWAY

EMPORIA4KT

DIGISTART – Support Ecosystems for Digital Startups

AudaCidade

VortalInterData

AI4CC (Automation & Intelligence for Contact Centers)

Life Cycle Analysis (LCA) study of two different methods of manufacturing large-sized locks over 1.5 meters in diameter

European Manufacturing Survey

OUR FACILITIES ARE AVAILABLE FOR PhD STUDENTS TO SUPPORT THEIR RESEARCH PLAN. EXAMPLES OF PhD THESIS ARE:

Integrated model for optimization of aircraft maintenance management: an approach to forecasting and capacity planning

Towards climate change mitigation by sustainable wire-arc additive manufacturing

Smart maintenance 5.0 in naval vessel context, resorting on TRIZ methodology

Impact on Seafarers for Energy Effcient Operation of Ships

Predictive Analytical and Planning Model for Industrial Urban Symbiosis

Waste to 3D printing: the development of additive symbiotic networks

The impacts of additive manufacturing on supply chain resilience

Driving manufacturing systems for the Fourth industrial revolution

THIS LABORATORY ALSO SUPPORTS WORKS DONE BY MASTER’S AND BACHELOR’S STUDENTS. SOME DISSERTATIONS INCLUDE:

Augmented Reality as an Autonomous Maintenance Tool

Application of ARIMA models for maintenance capacity planning: A case study in the aeronautical context

Application of natural language processing (NLP) models to value maintenance data

Development of a robotic assembly cell used in the assembly of mechanical components

Application of a TLS hybrid system to a multi-model assembly line