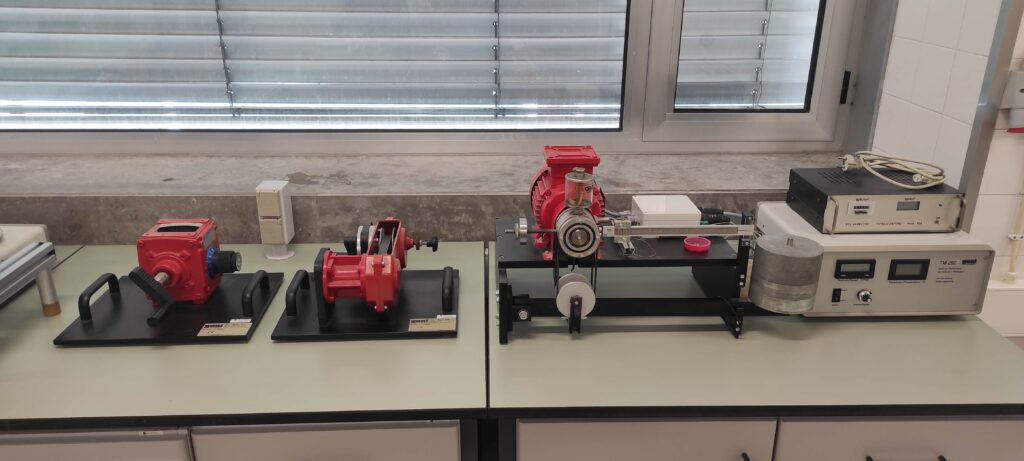

The Machine Design Laboratory’s mission is to provide support for the conception, design, and construction of equipment and its components. It has materials testing capabilities. The laboratory can develop functional prototypes of machines and components using different subtractive and additive manufacturing technologies. It has 2D and 3D digital image correlation equipment and computational capacity for geometrical modelling and numerical simulation.

EQUIPMENTS AVAILABLE IN OUR LABORATORY INCLUDE:

Mechanical lathe Shaublin Belivard 102-80

Bosch GMC800 SJ Radial Cutting Machine

EFI drilling machine

DeWalt DCD700 battery drill

LETAG EE5 grinder

30T MEGA KMG-30A press

ONGOING PROJECTS INCLUDES:

The AneurysmTool project (FCT.IP, DOI: 10.54499/PTDC/EMD-EMD/1230/2021)

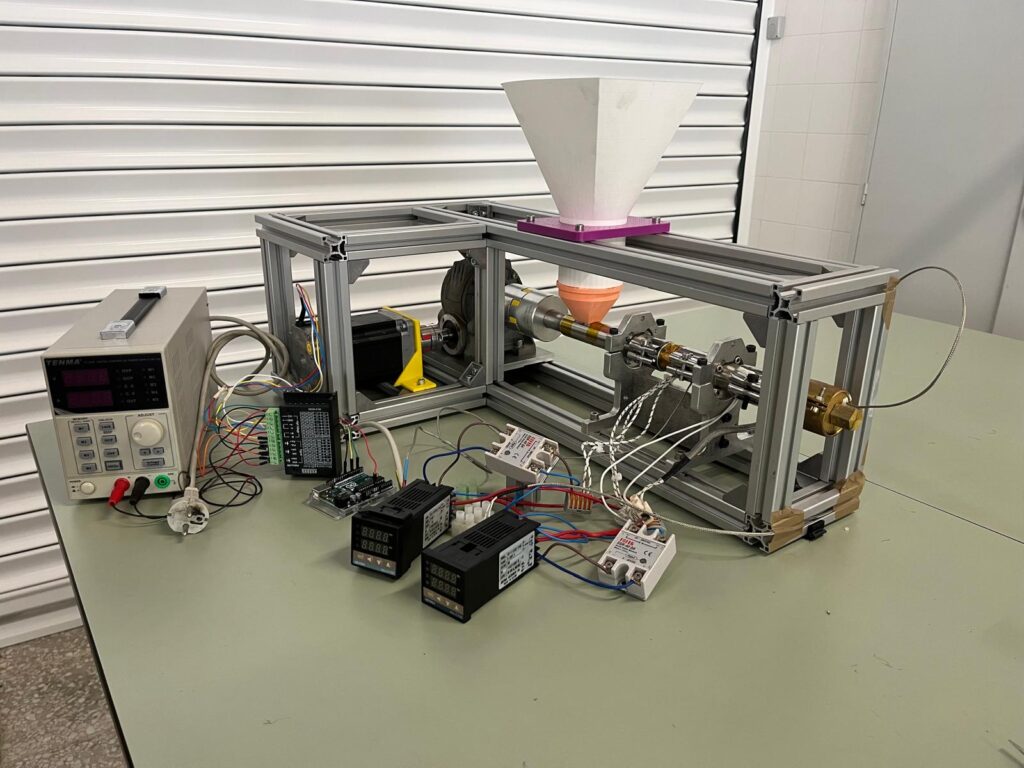

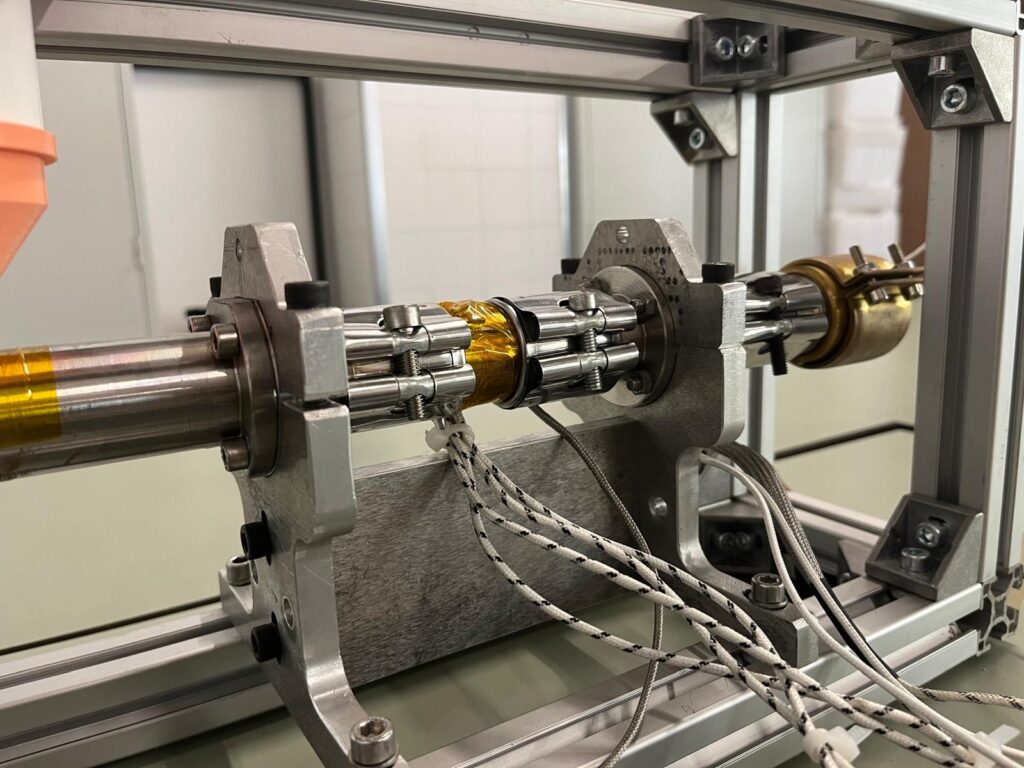

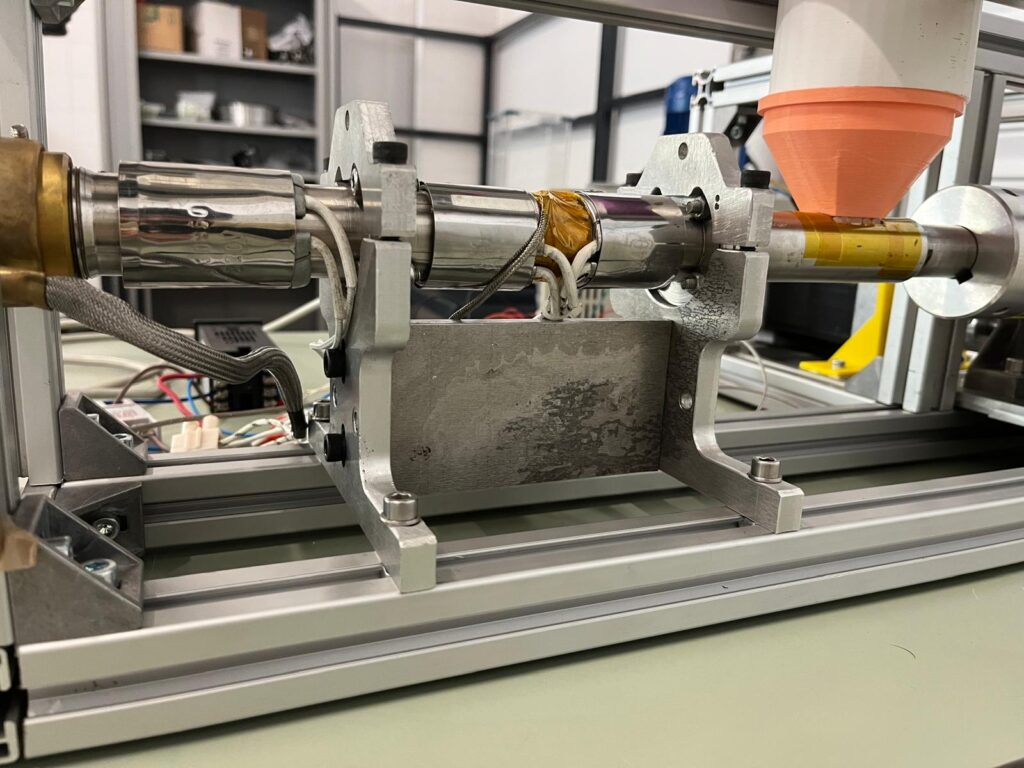

FIBR3D – Additive manufacturing based hybrid processes for long or continuous fiber reinforced polimeric matrix composites

Smart Composites, refª. PTDC/CTM/66380/2006

Redesign of exhaust systems for naval gas turbines, refª. PTDC/EME-PME/67071/2006

OUR FACILITIES ARE AVAILABLE FOR PhD STUDENTS TO SUPPORT THEIR RESEARCH PLAN. EXAMPLES OF PhD THESIS ARE:

Design and production of tools for the automotive industry using Wire-Arc Additive Manufacturing (WAAM)

A Data-Driven Machine Learning Approach to Predict the Fatigue Crack Growth of Lightweight Alloys for the Aeronautics Industry

On the certification of additive manufacturing for the aeronautical industry

Recycling strategies for Glass Fibers Reinforced Polymers and their use as reinforcement materials in additively manufactured components

THIS LABORATORY ALSO SUPPORTS WORKS DONE BY MASTER’S AND BACHELOR’S STUDENTS. EXAMPLES ARE:

Machine Design, Theory and Methodologies of Design, Additive Manufacturing, Biomechanics, Fracture Mechanics, Failure Analysis, Fatigue Life Resistance and Fatigue Life Prediction